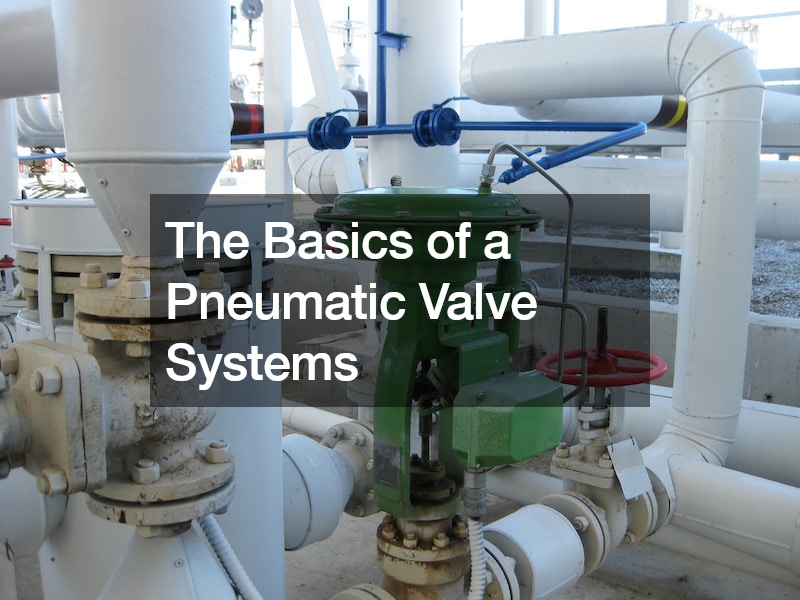

A pneumatic valve system and a pick and place robot are integral to modern industrial automation. Pneumatic valve systems are the control centers regulating compressed air and gasses in various industrial applications. These systems ensure that pneumatic equipment and machinery function properly. The YouTube video delves into the operations of these systems in an industrial setting.

Pneumatic Valve Systems Explained

Firstly, these systems control the flow of compressed air and gas in pneumatic systems. In addition, it regulates the movement of actuators and other components. Secondly, compressed air or gas actuates the pneumatic valves and enters the valve body to shift components and control the flow, direction, and pressure of the air or gas.

Furthermore, a pneumatic valve system consists of various components. For example, control devices, valves, actuators, pneumatic piping, and tubing. In addition, there are various types of pneumatic valve systems, such as directional control valves, flow control valves, pressure control valves, and shuttle valves.

These systems work in various industrial applications. Examples include manufacturing automation, robotics, automotive assembly, packaging machinery, and pneumatic power tools. Finally, pneumatic valve systems are controlled manually, through a solenoid, mechanically, or pilot-operated.

A pneumatic valve system and a pick and place robot work in tandem to streamline manufacturing processes. These systems enhance efficiency, control, and productivity. They work together to unlock the full potential of automation in production.